Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal.

Bending 11 gauge sheet metal.

This is my version of a homemade bending brake for 10 gauge sheet metal.

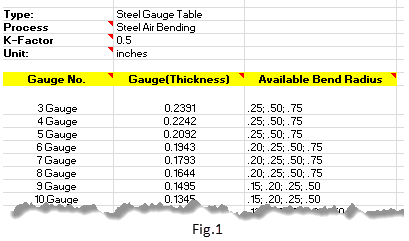

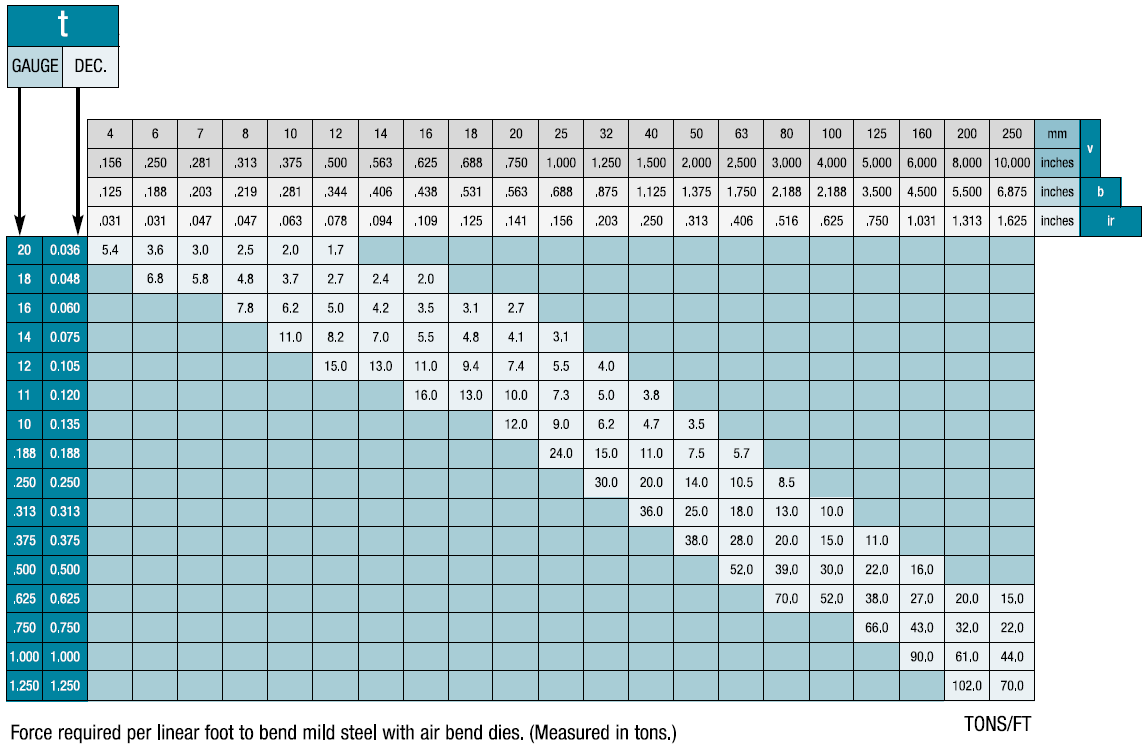

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

0 017453 x 90 x 0 020 0 33 x 0 024 0 0438558984 inch bend allowance keep in mind that some metals are more brittle than others.

The material thickness will be measured in decimal form not by the gauge number.

Category thickness minimum bend bend radius.

Sheet metal is metal formed by an industrial process into thin flat pieces.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered.

The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance.

22 gauge 0 030 0 76 mm 0 5 12 7mm.

Shop 13 manual bending brakes at northern tool equipment.

We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.

For example 18 gauge steel according to a gauge conversion chart is 0 0478 inch or 1 214 millimeter.

It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

22 gauge 0 030 0 76 mm.

Thicknesses can vary significantly.

You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k.

As an example if you want to bend 24 gauge sheet metal at a 90 angle the calculation would be.

Total build cost was.